The cost of fitments made by 3D printers depends mostly upon the material price.

In contrast with the traditional productions ways where an object's production price is

a result of the used material cost, fabrication and processing, the laser polymerization

technology prime cost has only two components: the used material amount and time of fabrication. The time

is defined by the objet overall dimensions and the printer heads width. A 3D printer laser head polymerize each next level in one or many head's passes. Number of them is a factor defining the total fabrication time.

Concerning the second component - the material cost, since the geometrical complexity

is not a matter of the laser polymerization fabrication process the less used material

the less prime cost is. Hence the general idea consist in construction of complex geometries that keep

the object mechanical properties tolerable from the daily maintenance point of view. For example added hollows may essentially reduce a

product final price.

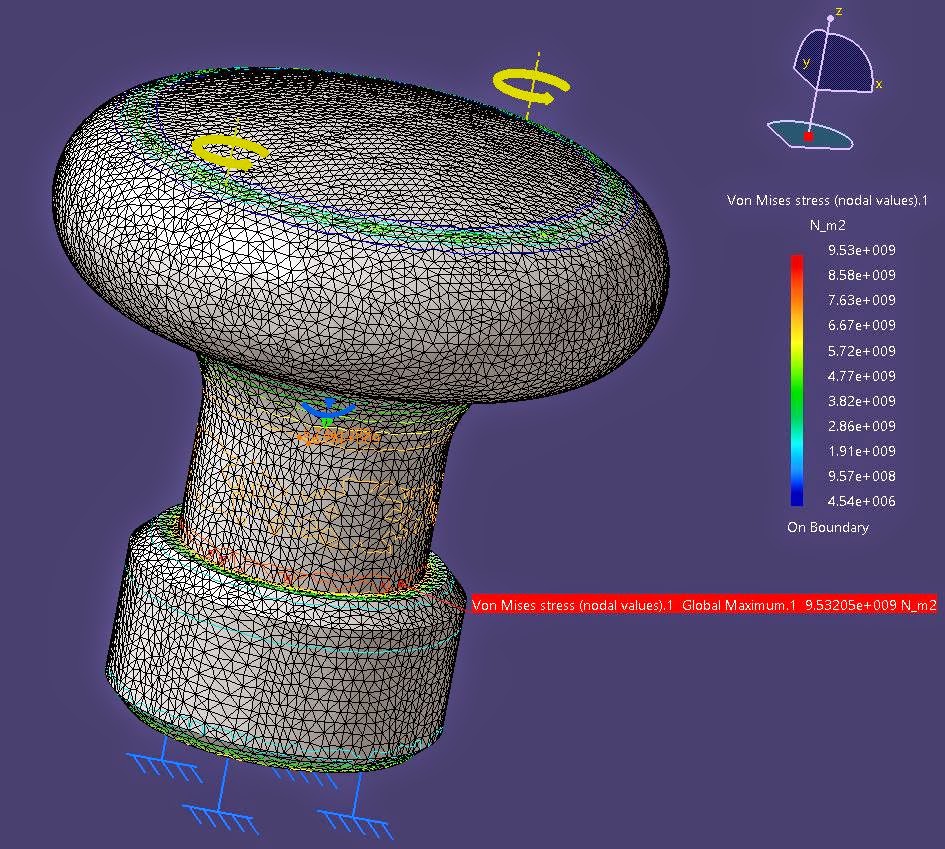

The figures show one example. This is a 3D fabricated door's handle. In spite of many hollows it has sufficient torsion strength.

Aucun commentaire:

Enregistrer un commentaire